-

19JanJanuary 19 , 2023

Special offers on Mitsubishi OEM Consumables and Wires

-

27AprApril 27 , 2022

12th Die & Mould India International Exhibition

-

23AugAugust 23 , 2021

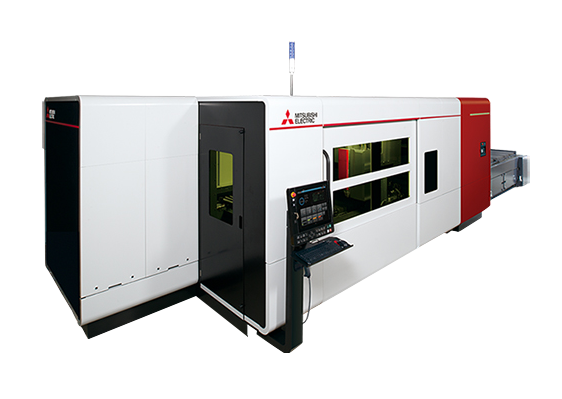

GX-F Series Fiber Laser Processing Machine Development Story

-

20JulJuly 20 , 2021

FIBER LASER Webinar

-

12JulJuly 12 , 2021

OKI Electric Cable EDM Wire.!!!

-

07JulJuly 07 , 2021

FIBER LASER Webinar

-

08JulJuly 08 , 2021

SG8 Sinker EDM is now ready for

Demo & Test cut !!! -

01DecDecember 01 , 2020

Fiber Laser GX-F40 is Ready for Demonstration!!

-

23OctOctober 23 , 2020

Navratri Celebration 2020

Welcome to

MC Machinery Systems India Private Limited

(formerly MC Craftsman Machinery Private Limited)

MC Machinery Systems India Private Limited (MMSI) is established in India for Sales and Service of advanced industrial machinery by Mitsubishi Corporation (MC), Japan together with Mitsubishi Electric Corporation (MELCO), Japan, MC Machinery Systems, Inc., (MMS) USA, Mitsubishi Corporation Technos (MTS), Japan, and Mitsubishi Corporation India Private Limited (MCI), India.

View all

Products & Solutions

One source. Endless expertise.

-

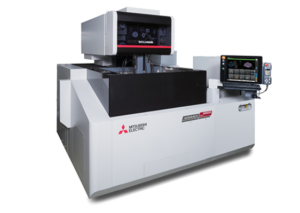

EDM Processing Solutions

-

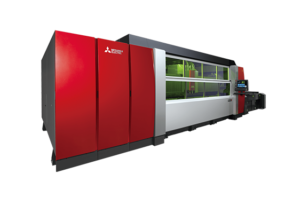

Laser Processing Solutions

-

IoT Systems

-

Parts & Consumables

-

Service & Application Support